Thursday 28 April

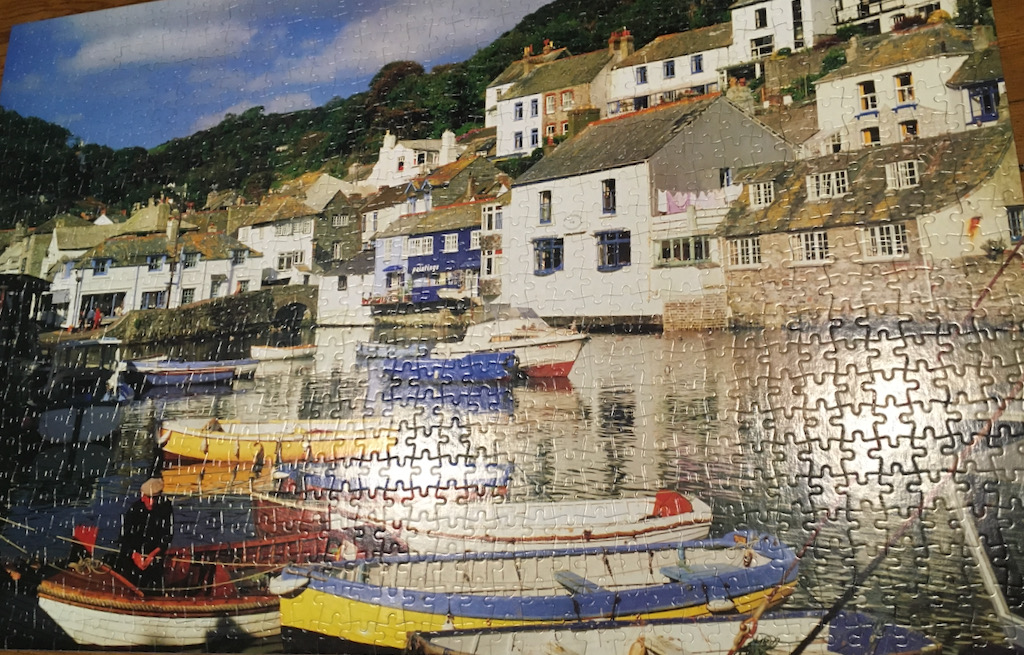

I was late again today but the team had let themselves in and opened the front door. The reason for my lateness was because I had been carefully deconstructing the jigsaw puzzle Harry had leant me as I didn’t want to loose any pieces. It had been a challenge as well as a totally engrossing task to complete it. It was a picture of wooden boats from my heartland of Cornwall. The scene in Polpero harbour must have been photographed in the late sixties/early seventies because most of the boats are traditionally clinker built dinghies where the planks are riveted to steam bent oak ribs.

Thank goodness we now have epoxy glue and clinker plywood to make the building more accessible to amateurs like us.

Paul and Adrian got on with the job of planing down the stems so they taper from 50mm to 30mm thick at their out section.

John S had arrived with his dog Archie who was very well behaved while John got on with the job of planing of the tabs on the planks for the next boat.

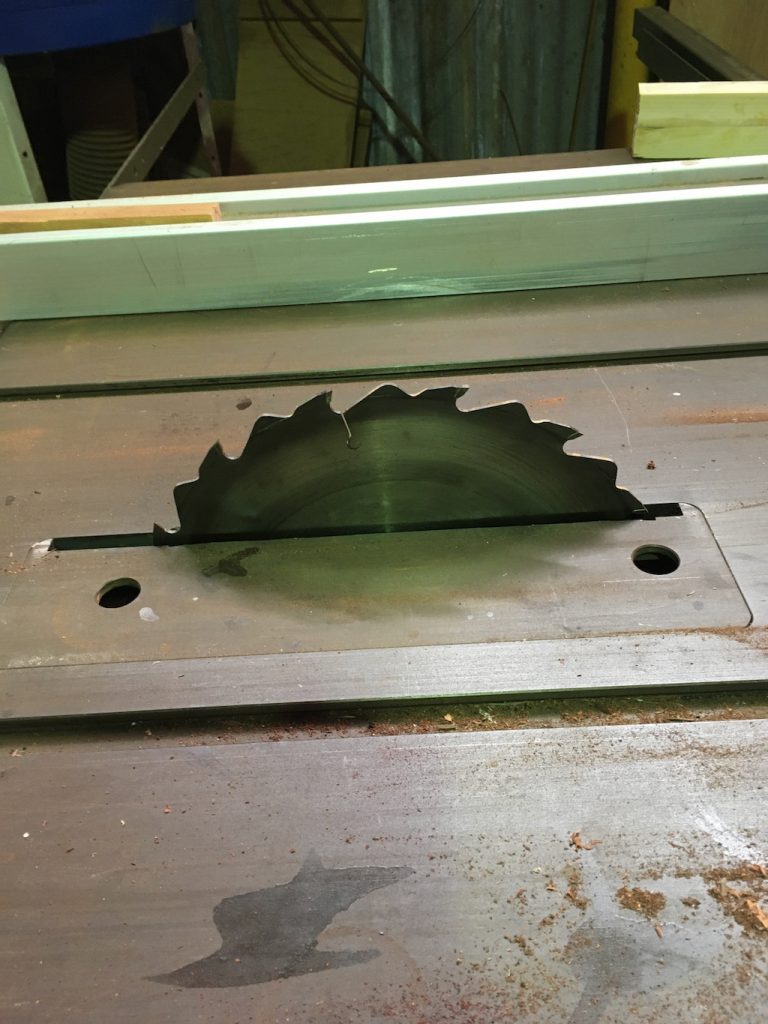

After cleaning up the glued and almost straight keel section JP, Nick and I had a shot at using Harry’s bench saw to cut the same bevel as the stems into it. After much vexing over the exact angle to cut and how to achieve it safely on the bench saw we started pushing it through but although it did cut it it was slow going. A combination of the wrong saw blade and blunt teeth were probably to blame. So we went to plan B and rang Pete to see if he was free to cut it. He was and so JP and I put the keel timber on the side of the car and hung onto it for the short trip round the corner. I was just saying that I hope we don’t see any police cars when up the hill came the town’s boys in blue. I breathed easy when they turned off before passing us.

Pete made short work of cutting the bevel and we returned with a shaped keel timber.

Roger had been around at tea break and talked about the different circular saw blades. Harry’s has multiple small teeth with tungsten tips for mainly cutting boards whereas Pete’s has far fewer teeth and a sort of secondary tooth that is better for ripping (cutting with the grain) on thicker timber. It certainly did a great job on our soft Hoop pine. Thanks Pete! Sorry I forgot the Whisky glasses again!

Back at the shed I used my new 6mm roller guided router bit to cut a smooth bevel on the outer edges of the keel. We then had to make a decision on the angle of scarf joint we were going to use. In the end Harry’s drop saw made that decision for us (50 degrees and as close to each end as we could to maximise its length. We also used the drop saw set to the same angle on the aft stem and married the two up at the end of the day. Not a bad fit, just a little sanding to do on Monday morning.

At some stages it had got too noisy in the shed for Archie and he took himself outside in the sun.

See you on Monday for the glueing up.

Cheers Dave