Tuesday 1st November

This morning I went around to Denmark Mobile Welding to get the paperwork for registering the trailers. Dan was in a bad way as he had lost one of the bits of paper and then on top of that his printer wasn’t working. I was going to get a print of the receipt from Tony next door when Dan came out with the missing piece of paper that had blown into a corner on the floor.

I then went into the shed where Dr John and Paul were waiting for me. They both got on with sanding yesterday’s resin coat with wet and dry while I went off to the Denmark Shire offices to register the trailers and get number plates. The usual red tape was out to trip me up. After filling in the forms I was politely told that I needed the Association’s incorporation certificate and ABN. So I trundled home to get the certificate, have a cup of tea and fill in another form in duplicate. Back at the Shire things went smoothly and slowly and I entertained myself by listening to the driving examiners who were testing young people. This morning there was one successful driver, one unsuccessful (in tears) and one could not start as she had borrowed a friends car which turned out to be unregistered as of a couple of days ago, poor thing.

With newly minted DE plates I returned to Dan so that he could fit them and then went back to the shed where Veronica had joined the sanding crew.

Dr John was sanding the footrests which came up well with the orbital sander.

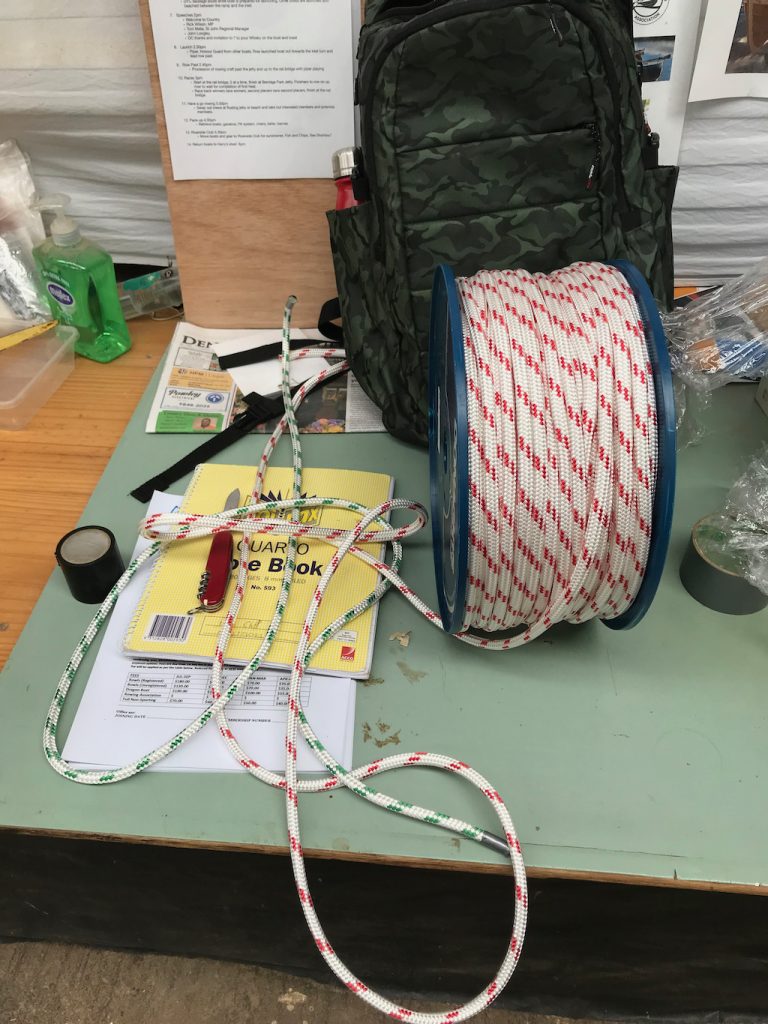

JP had been in with his stock of rope from which he is giving the skiffs a little. He also had a hot blade cutter which made it easy to cut the rope cleanly. I cut a meter and a half of red flecked 9mm rope and the same length of green flecked rope for the port and starboard rudder yoke control line respectively. I then cut an 8m length as a tow rope and mooring rope and repeated the exercise for boat 2.

Dan texted to say a trailer was ready so I went around and picked it up and brought it back. I then searched our wood pile for suitable wood to make the stretchers to support the underside of the hull but nothing was forthcoming. I went over the road to Thorntons Mitre 10 and bought 6m of treated 90*45 pine which they kindly cut into 1.5m lengths. Back in the shed I was able to shape the rear end into a gentle slope to receive the boats as they come on to the trailer. Veronica dropped back in with some leftover carpet to cover the timber and protect the paintwork. I didn’t get far before 3pm when the committee turned up for a meeting. After the meeting I attached the wooden stretchers to the adjustable brackets and that was all I had time for before nipping around to Dan’s again for the second trailer.

I’ll need some helpers at 9.30 am tomorrow to lift boat 1 onto this trailer to take it around to Denmark Signworks please.

Cheers Dave