Tuesday 30 August

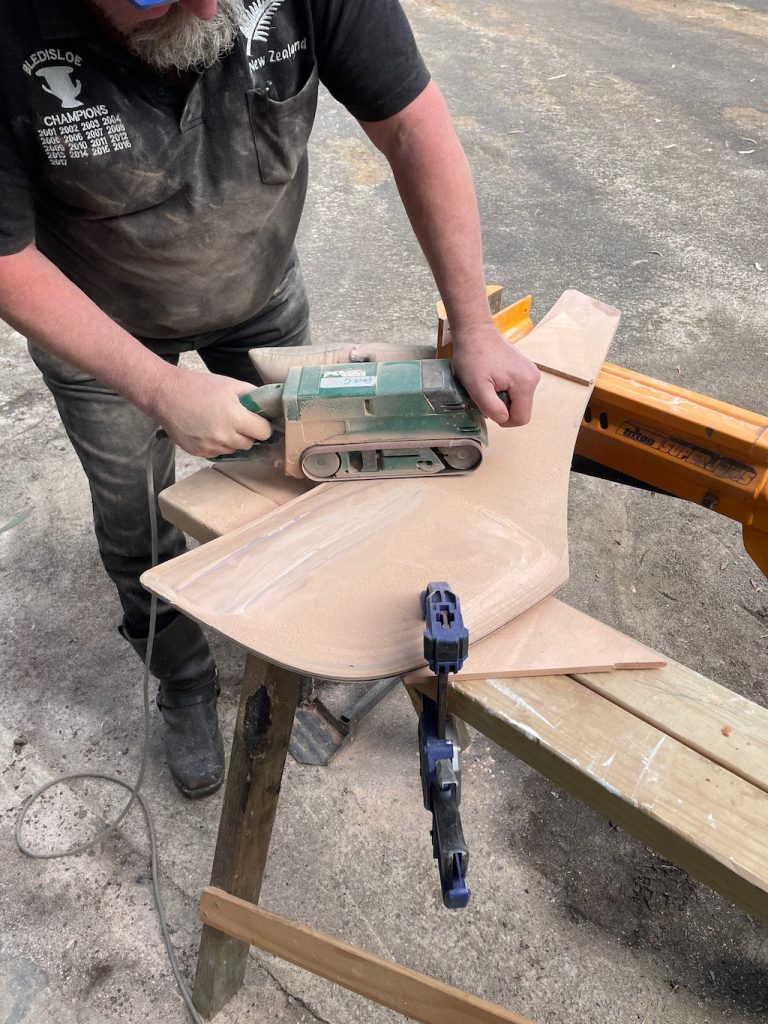

Russell was at the shed when I arrived this morning keen for a cup of coffee and a look at the progress we had made. He likes the power tools so I got him set up with boat 2’s rudder blade and the belt sander.

JP arrived with new plans for the rowlock pins involving glueing the steel pins into the centre of a tapered Wooden thole pin. My wife, JB, then delivered the banner which I had forgotten and brought our now lonely dog, Kester into the shed for his first visit. Sadly we had to have our lovely brown Labrador put to sleep yesterday, she was 13.5 yrs old.

Stuart joined us and I set him the job of making the bow passenger seat which he took on. The seat is lower down in the hull than the cox’s seat and Stuart took a different approach to me. I started with the supports and then using a couple of MDF offcuts worked out the shape of the seat to fit into the supports. Stuart used the offcuts and tape to get the shape and location of the seat without the supports and then cut it out of 9mm ply. We are going to laminate a 6mm veneer of Sheoak onto the top of the ply.

JP made ready boat 2 for lifting and tried with a jack to unstick it from the moulds without success even when I had been under the boat using the Adrian method of lifting with my legs it wouldn’t budge. I came out in workshop camouflage.

I went back to the cox’s seat and worked out how to divi up a piece of Sheoak into 6mm laths to laminate onto the plywood base. Then people started arriving for the spectacle of turning over the boat so we put the kettle on.

Geoff had baked scones for the first time and brought jam and cream to go on them. They went down a treat especially with Harry.

The Denmark Senior High School students were meant to have been with us but as it was country week the school buses had gone to Perth and there was no transport for them. By 11.30 we had a enough reasonably strong and able bodied people to lift the boat and its moulds off the building frame and take it out to the grass to be rolled over.

JP immediately started attacking the excess glue with the heat gun once the visitors had dispersed. Veronica started shaping the stern breasthook again. and I went on with the laminating maths and cut two identical ply seat bases for boat 2.

It’s been a proud milestone for all of us in the shed, getting to the point of turnover of the second boat. Now we have to finish it in two months (or maybe not). Thanks to everyone who has participated in the building project to date and our sponsors.

Talking of sponsors we have a new one, Nick Miller of Global Autocoat (www.globalautocoat.com.au) has agreed to supply the paints we will need for the boats which is very generous of him. Thanks Nick and Global Autocoat.

Cheers Dave