Thursday 18 August

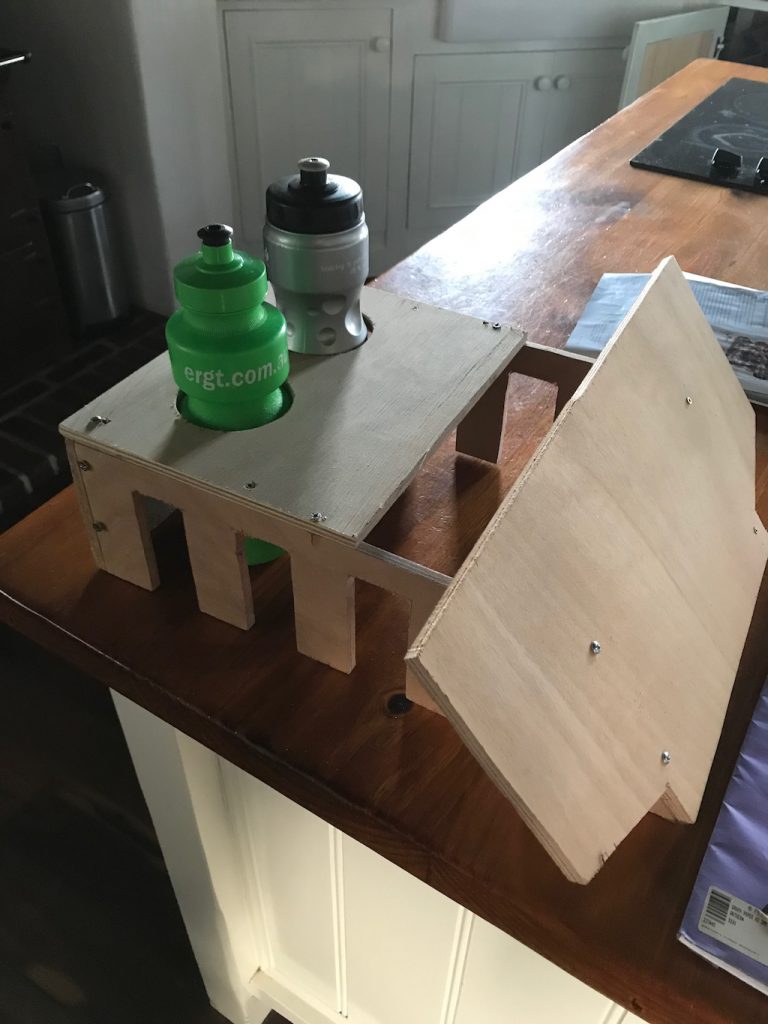

Yesterday I had mocked up a moveable footrest or “stretcher” as the rowers call them, in my shed and the first thing I did this morning was to see if it would work. Ted, Adrian and JP were on hand to discuss the merits of it and ways we would need to strengthen it up. I have a plan to make it dual purpose as a drinks bottle holder. Ted suggested adding a USB power point! JP climbed into the boat to test the seat positions and relative spacing.

Clem then turned up to get measurements for his quest in Perth for more rowlock pins. More discussion was had on the merits of upright vs orthogonal positioning of the rowlock pins and how to make illegal metal pins interchangeable with wooden thole pins which we will need eventually.

Adrian and Ted were joined by John I for the task of drilling and fitting the stems and keel to boat 2. I had bought bronze screws so that we can leave them in the boat once they have done the task of clamping the keel in place.

JP and I had a discussion about rowlock positions and the size, shape and angle of the plate that sits on the gunwale under the rowlock to protect the gunwale from the oars. We are going to make these out of more of his sheoak. We took a plank of sheoak up to Harry’s other shed and cut a 15mm thick piece off one side to use as a first pass.

Dr John had arrived with Archie who was accused by JP of putting a hole in his very dapper puffer jacket which would require more Fixamol to patch it. Dr John got to work on the rudders. Boat 1’s rudder needed rudder cheeks glued to it so he drilled two holes through the clamped up cheeks for a wooden skewer to go through and be used as a locating device when we are glueing them up at the end of the day. He also cut out two 9mm ply boards to glue onto the sides of Boat 2’s rudder blade for future fairing. Later in the day after Dr John had served morning tea we glued these items up.

After morning tea I tried to concentrate on marking up the thwarts with the position and angle of cuts required to get them to sit in place. Roger had put in a short appearance to help the crew on the keel dry fitting and it all had fallen into place. So leaving Ted to do some intricate wood work on the thwarts I moved into glue up mode with Adrian and JP.

When you’re in glue up mode you can’t get out your phone to take pictures which is just as well as I was getting a little frustrated trying to get the perfect fillet with the squeeze out glue along the keel. In the end it all came together really well and as the team dwindled away I stayed on determined not to waste any of the squeeze out glue by using it to improve the fillets around the frames in boat 1.

Ted had said his goodbyes and was off back to Perth with a promise to return. We had all enjoyed having him in the shed and giving it a crack. He had chiseled out the first frame indent in the thwarts and it fitted well.

Hope you have a good weekend. I’ll be taking our spare oars over to Nannup for their boat which I will bring news of hopefully.

Cheers Dave