Monday 2 May

I did manage to get to the shed first with Harry’s contraband jigsaws that JB had picked up in Albany. Everything was neat and tidy and ready for the final shaping of the stems and then the glueing of the keel into place. Nick got started on shaping the bow stem with the electric planer to speed things up. Colin, who had brought in a copy of the Southerly magazine with his article on me and the skiff building, cut out the frames from the remaining plywood sheet for boat 2. JP and I puzzled over the rudder cross section plans again and decided we needed to glue on 9mm sheets to thicken up the rudder blade section to get anything like the planned final section. John came in and went straight to work on knocking more of those tabs off the next set of planks. Nick found the electric plane was taking too much off in a hurry so he reverted to the hand plane to finish the job. We then gave the stems a finer sanding and routed a 6mm bevel into the outer edges.

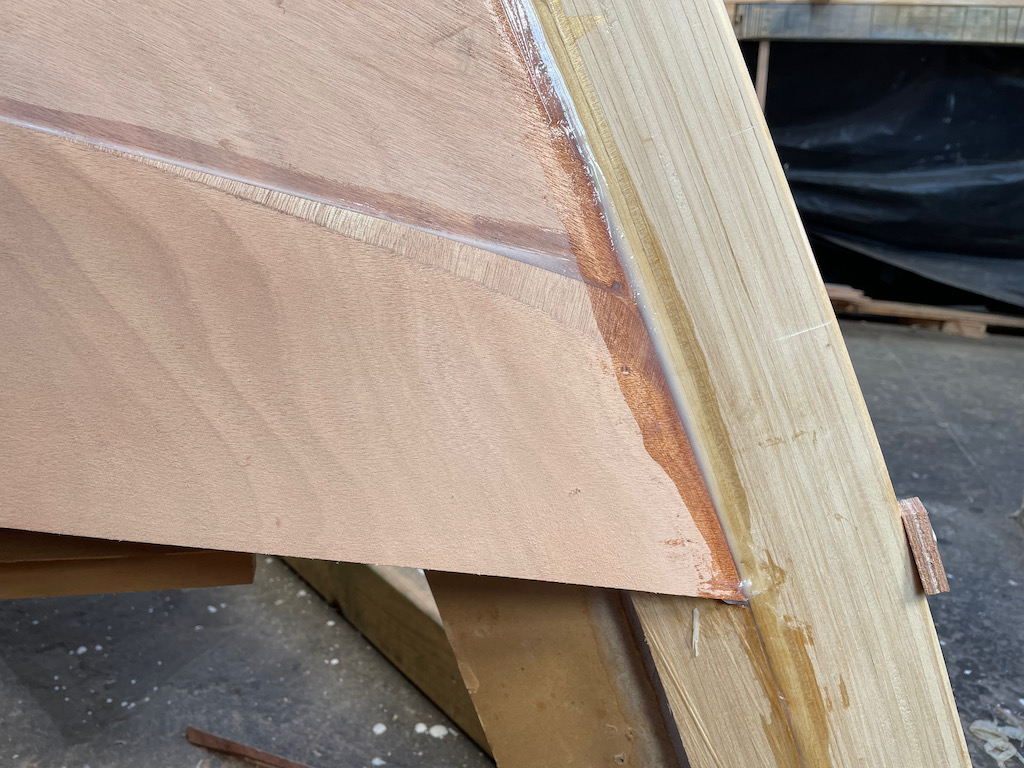

The trickiest part of the operation today was cutting that scarf in the picture above so that it would all fit together with the keel already tacked down in place. So much brain power went into it we had to stop for tea and biscuits. John seeing a looming crisis on the biscuit and cake front went off and baked a cake and some biscuits all delivered in nice wrappers, just like the ones in the IGA.

Harry was present to guide JP and I in the use of his drop saw to get this rather tricky cut through a piece of wood with no straight sides. We erred on the side of caution and had some sanding to do to get the final fit. Using temporary screws we had the two stems and the keel in a dry fit that was as straight and tight to the inner keel and stems as we could get it.

Cam the boat building teacher from Denmark Senior High School dropped in as we were deliberating on the keel and we planned how we would work with his class when they come in tomorrow morning.

With only an hour to go JP and I gloved up to mix resin and glue to glue up the keel and the rudder thickeners. The others left for other commitments and we got on with the job. JP learnt the hard way the symmetry of his pieces of rudder meant that they can only be glued on the right side. I put plenty of glue along the keel and then we screwed the stern stem in place followed by the keel and finally the bow stem. Only the stern stem had trouble relocating the dry fit screw holes and that was my fault for not putting a locating mark on the wood. Presto we really do have a boat!

We will be back tomorrow to clean up and then fill the clinker lands with cove fillets to protect the edge grains of the plywood. There will be more work on Boat 2 including laminating up the stems and finishing the clean up of the tabs.

If you missed the Southerly magazine here is the article Colin and I wrote.

Cheers Dave